CNC Line Setup Rapid Upskilling Program

Team up with WBLC to upskill your current employees in 3 months.

eLearning + Weekly Online Classes + Coaching + Assignments

eLearning Overview Demo

Overview Demo – 10 Minutes

For Plant Managers, Supervisors, and Trainers.

Provides comprehensive overview of the program modules.

CNC Line Setup elearning Modules

Week 1 - Intro To CNC Manufacturing

- CNC Terminology

- General Shop Safety

- CNC Mill + CNC Lathe

- CNC Manufacturing Shop Floor Tour

- CNC Machining Videos

- CNC Machined Parts – Common Features

- Shop Floor Assignment

- Intro To CNC Manufacturing Test

Week 2 - Core + CNC Mathematics

- Addition and Subtraction

- Multiplication and Division

- Fractions

- Statistics

- Measurement

- Ordinate Dimensions

- Geometry

- Trigonometry

- Trade Calculations

- Shop Floor Assignment

- Core + CNC Mathematics Test

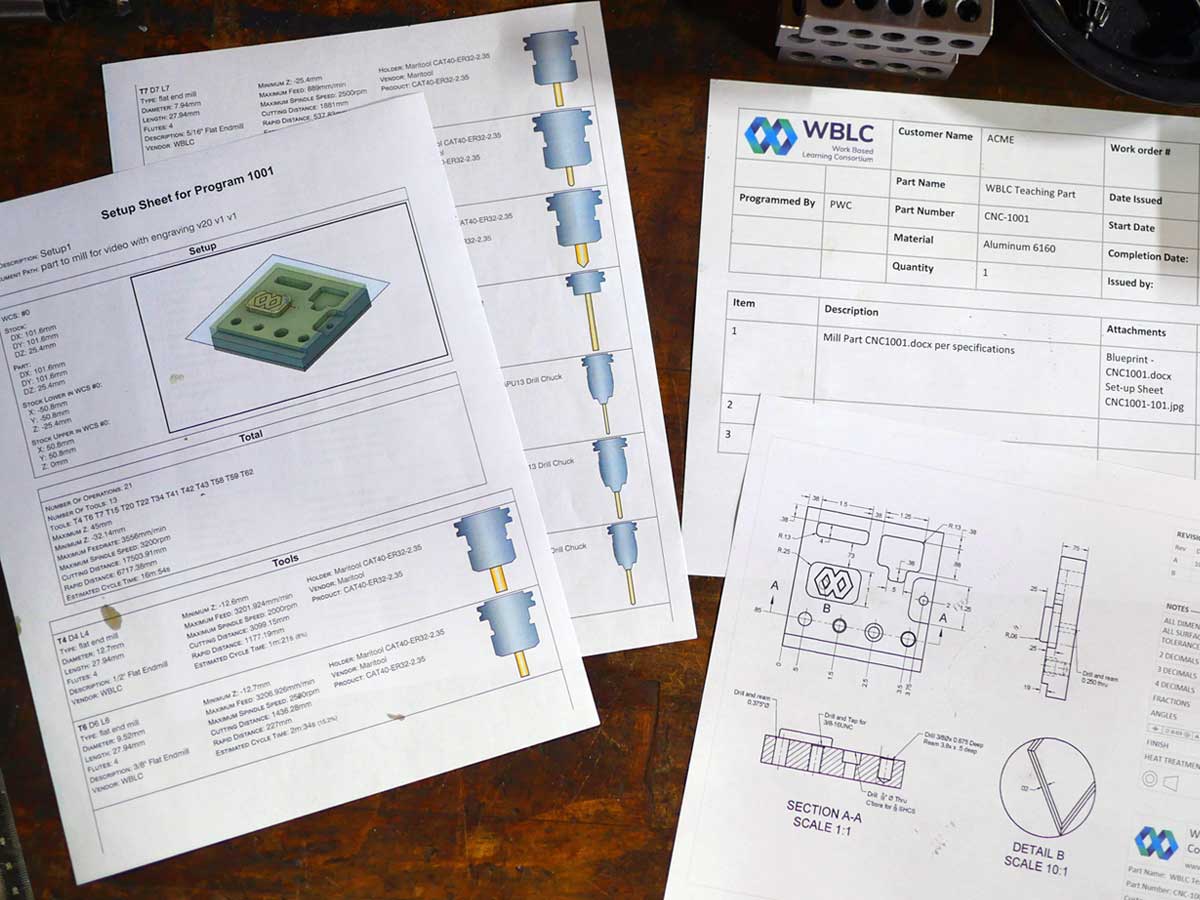

Week 3 - CNC Work Documents

- Blueprint Basics

- Parts of a Drawing

- Understanding Dimensions

- Geometric Dimensioning and Tolerancing

- Reading Blueprint Dimensions

- Work Orders

- Tool Set Up Sheets

- Linamar Work Documents

- Shop Floor Assignment

- CNC Work Documents Test

Week 4 - Your CNC Toolbox

- Tools For Measuring

- Tools For Material Handling and Applying Force

- Tools For Grasping and Fastening

- Tools For Shaping and Deburring

- Tools For Cleaning

- Shop Floor Assignment

- CNC Toolbox Test

Week 5 + 6 - CNC Machining: Materials

- Materials Used In CNC Manufacturing

- CNC Surface Finishes

- Shop Floor Assignment

- CNC Machining: Materials Test

——————

- EXAM 1

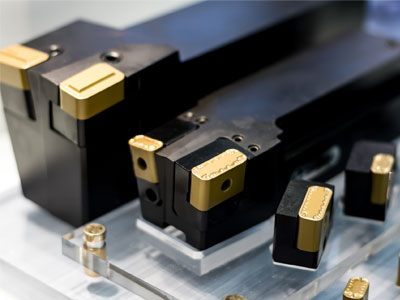

Week 7 - CNC Cutting Tools & Fixtures

- How CNC Cutting Works

- CNC Mill Cutting Tools

- CNC Lathe Cutting Tools

- Cutting Tool Materials, Fluid, & Wear

- CNC Mill & Lathe Holding Devices

- Shop Floor Assignment

- CNC Cutting Tools & Fixtures Test

Week 8 - CNC Controller, Offsets, & Feeds

- CNC Controller

- CNC M and G Codes

- CNC Offsets and Compensation

- CNC Feeds and Speeds

- Shop Floor Assignment

- CNC Machines Mill & Lathe Test

Week 9 - Operating A CNC Mill

- CNC Mill – Planning A Job

- CNC Mill – Setting Up A Job

- CNC Mill – Milling A Part / Achieve First Off

- Shop Floor Assignment

- Operating A CNC Lathe Test

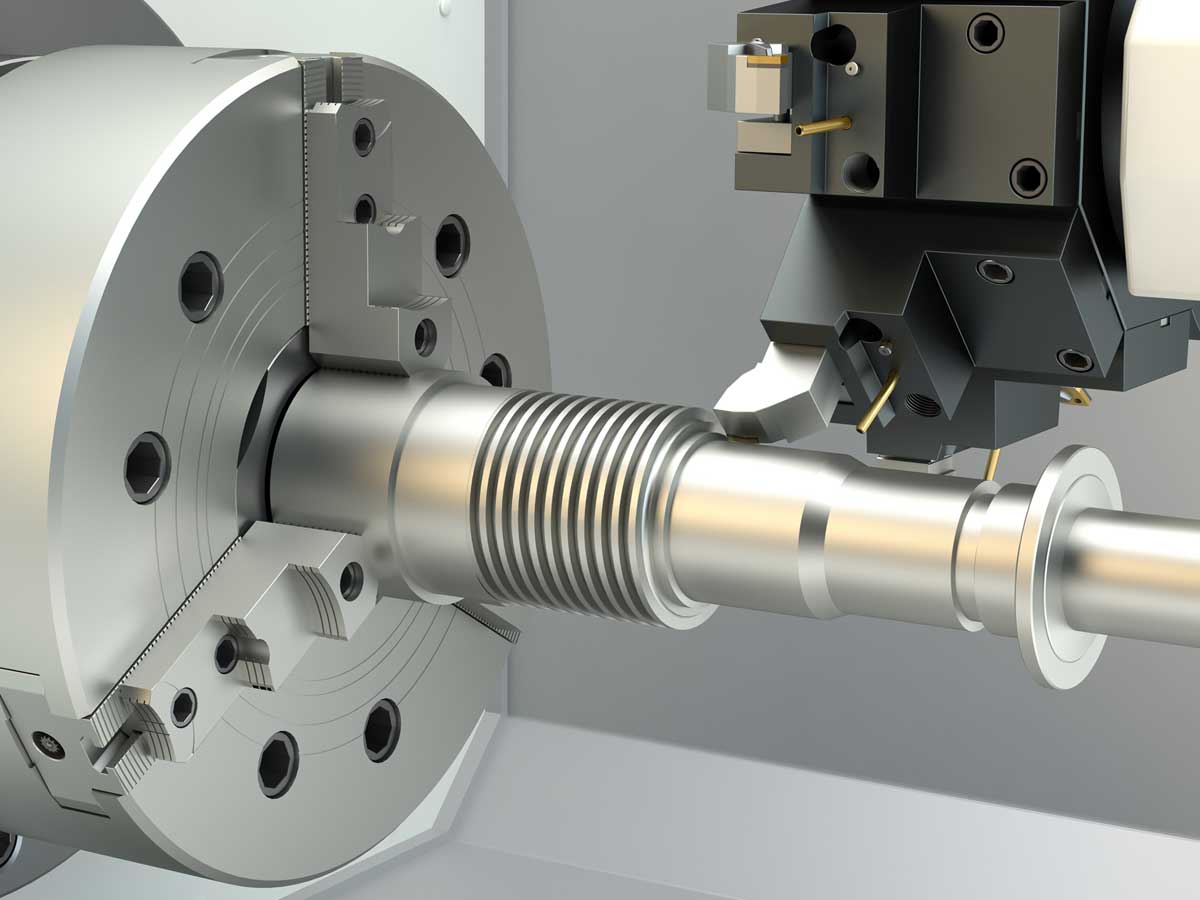

Week 10-11 - Operating A CNC Lathe

- CNC Lathe – Planning A Job

- CNC Lathe – Setting Up A Job

- CNC Lathe – Turning A Part / Achieve First Off

- Operating A CNC Lathe Test

- Shop Floor Assignment

——————

- EXAM 2

Between Weeks 12-14

Final Practical Assessment

Weekly Online Classes, Monitor Coaching + Trainer Training

Weekly Virtual Classroom Sessions

Our E-Learning Instructor works with participants every week over Zoom to discuss the content covered in the e-learning, answer questions, and support the participants in their learning journey.

The e-learning instructor also discusses the Shop Floor Assignments as they offer practical hands on direction to learn about all elements of CNC machines.

Monitor Coach Visits

Our Monitor Coaches monitor the progress of the participant and conduct assessments as part of the certification process.

They also support your Trainers by answering questions and providing guidance on the program.

Technical Trainers Workshop

The Shop Floor Effectiveness for Technical Trainers (SFETT) Program improves your Technical Trainers effectiveness in managing employees via two 90 minute workshops.

Trainers find they are far more confident and get more out of employees after attending these workshops. Learn more >

WBLC Certification

WBLC certifies participants after they have successfully passed the tests and exams in e-learning, demonstrated understanding of topics to the e-learning Instructor, and demonstrated proficiency on the shop floor to your Trainer and the Mentor Coaches.

Let’s Get Started

Talk to your Plant Human Resources Director