When Work-Based Learning Consortium (WBLC) first started to build its e-learning program years ago, the purpose behind the initiative was to help companies to train their employees at the worksite and avoid the geographic limitations often associated with classroom training.

To give some context, part of the original CNC Machinist training at the time involved classroom and shop floor instruction in the Greater Toronto Area (GTA). This worked well for some companies, but for companies outside of the GTA, it often meant that staff had to be bussed into Toronto for classroom training for several weeks at a time. It wasn’t the ideal situation.

Rod Jones, Managing Director of WBLC says they recognized that a different approach was required and efforts were made to create an e-learning component.

| “We knew that the e-learning couldn’t be just a talking head (of) a classroom instructor.” – Rod Jones, Managing Director of the Work Based Learning Consortium |

“We knew that the e-learning couldn’t be just a talking head,” says Jones. “It’s not videotaping a classroom instructor. It has to be interactive and engaging for the trainee. But the e-learning also has to be focused on the knowledge and skills that are required in order to perform the job well and successfully.”

Today, WBLC’s e-learning program is part of a comprehensive approach to training and upskilling, which includes interactive e-learning, e-instruction, train the technical trainer workshops, shop floor assignments, on-the-job training, technical language training, monitor coaching and last, but not least, certification of successful trainees.

“Imagine you’re the student, you’ll do some e-learning modules, meet weekly with an e-instructor via a video conferencing program, such as Zoom, and receive practical, hands-on assignments from a technical trainer that reinforces earlier e-learning,” explains Reema Duggal, a lead for the virtual learning initiatives with WBLC. “Mini quizzes help trainees to master each training module. Ultimately, after completing the training, the trainee is assessed by a mentor coach and, presuming they pass, they are certified for the position.”

WBLC’s Work-Based Learning programs consistently achieve success rates above 90%.

Choosing the Best Way to Present Information

| “We are very focused on creating a high-end e-learning experience that is highly effective at passing along all of the knowledge and skills required to successfully complete the training,” – Reema Duggal, Virtual Learning Lead, Work-Based Learning Consortium |

Duggal explains that e-learning builds on technical learning outcomes and technical knowledge elements that were initially defined before the learning programs are created. This involves gathering the knowledge and skills that are required for a successful performance on the job from industry experts, and subsequently translating that information into detailed, digestible units of information.

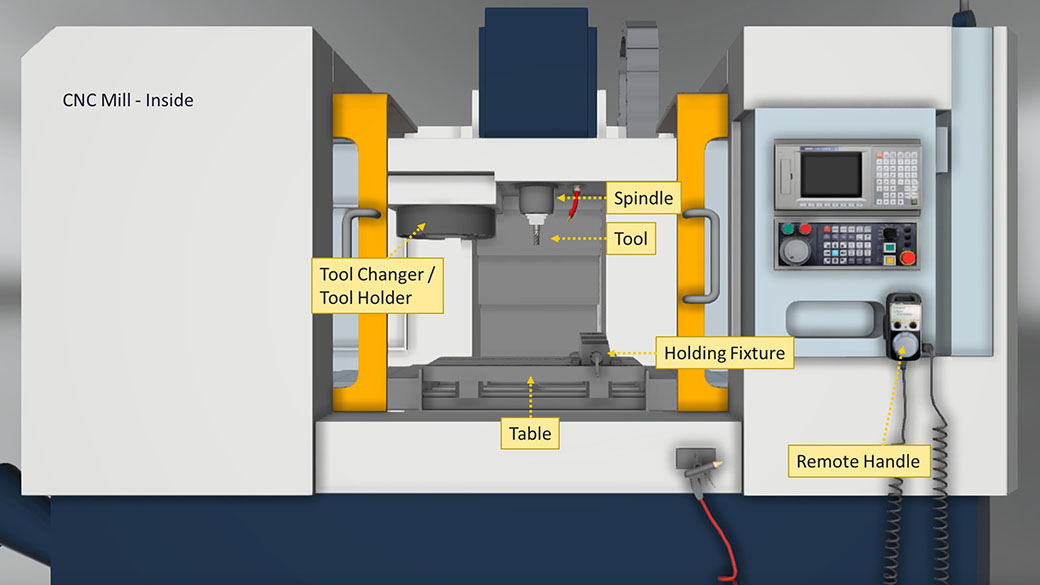

For example, the early portions of the CNC Machinist program involve teaching the trainees about the machines themselves. Parts of this particular module use images and text, animations, and video. The trainee moves slowly around the outside of a CNC machine and then into the inside, showing parts and learning terminology related to the machine. As the trainee progresses through the e-learning modules, they take periodic quizzes and can’t progress to the next stage until they’ve answered the quiz 100% correctly.

“The pace of the video when teaching the terminology of the CNC machine has been carefully set to ensure new machine operators can easily absorb and comprehend all of specific information they need to know,” Duggal explains. “They are quizzed as things move along. A quiz is typically two to five questions … simple questions … but they must achieve 100% on the quiz before moving to the next stage. The key is for them to know the material. We’re all about comprehension.”

Example of Animation from the WBLC Mold Maintenance Technician e-Learning Program

Some of the modules feature considerably more videos as they demonstrate more complex operations, instructions or tasks. For example, the trainee might be shown a static image of a task they’ll be required to complete, followed by a short video that vividly demonstrates how to complete the task. Also, the e-learning program teaches shop math and trade calculations, introduces to work documents, tool set-up sheets, the tools they’ll use, materials that they’ll machine with, shown the different cutting tools and operations, and then they’ll be shown how to mill a part as well as how to turn a part.

“With blended e-learning, we want trainees to learn the material, work on it out on the shop floor, pass the mini quizzes, and then move along to the next level in the training,” says Duggal, who describes blended learning as not just one thing, but many things that come together to reinforce the learning. “Throughout the training, we’re constantly trying to create a discussion and an interaction based on what they’ve learned. We’re trying to give them competency and expertise that will help them succeed.”

“After experiencing our training, people often comment that what we have created is very comprehensive” Duggal adds.

Tailoring to Each Industry

In addition to developing content, WBLC also adapts the style of the training to reflect the industry being trained. For example, the e-learning created for CNC Machinists has a very different tone from the material created for the Graphics Installer Technician in the sign industry.

“With the graphic installer technician program, our approach is a little less industrial and a little more artsy,” explains Duggal. “We’ve delivered a different tone because that reflects how the people carry themselves and interact with one another. Whereas, the CNC Machinists tend to be more structured. Each industry has a different kind of energy and we want that reflected in our training.”

Beyond tone, the sequence in which elements are taught also can vary significantly. For CNC Machinists, the section about materials is introduced in the fifth module, but for the Graphics Installation Technician, the materials section is the second module because it is so crucial that trainees understand vinyl and what surface it can be installed on. Conversely, with CNC Machinists, they are taught about the machines and the parts first, then math and measurement, before turning the trainee’s attention to materials (e.g., milling steel).

“The focus is always on the trainee and what content will work best for them,” Duggal adds. “While it’s subtle, it can really make an important impact.”

Determining the Best e-Learning Approach

“We have an experimental mindset when it comes to developing e-learning and training programs,” says Duggal. “Today, animation may be the most effective way to teach something, but tomorrow some kind of AI transformation may be the best method. We’re always looking for new and effective ways to engage the audience. It’s about opening your eyes and saying ‘what’s the art of the possible’.”

As an example, learning and understanding technical language is one thing, but knowing how to weave it into general conversation on the shop floor is something else. For some of the trainees, it is further complicated by the fact that English may not be their first language. So WBLC decided to turn to artificial intelligence and create short simulations where trainees can practice weaving the terms into conversation.

Working with British Columbia-based artificial intelligence (AI) conversation company, Virtro Technology, WBLC created simulations to teach trainees how to integrate approximately 70 technical terms into regular conversations with managers and co-workers. During the AI simulations, trainees can practice and receive instant feedback. It’s proven to be remarkably successful.

“At the end of the day, what we’re doing is good teaching, good story telling and encouraging good interactions. It’s a fascinating and rewarding part of our industry, and what we do can really make a difference in the everyday lives of our clients,” says Duggal.